Function

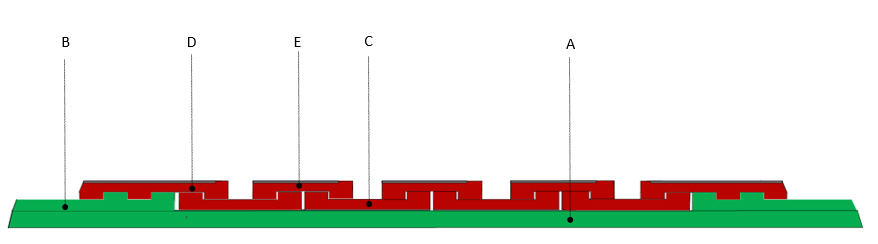

-Collars

C transfer compression forces by closing adjacent gaps.

-Collars

E transfer tension forces when the pipeline elongates in tension.

-Collars

C transfer tension forces to collars B or alternatively compression

forces to part A.

-Collars

D closing the space at field welds, transfer compression forces or

alternatively tension forces to collars C.

-The

section modulus of the collars are added to the pipeline when the

slots and gaps close resulting in discontinued yielding.

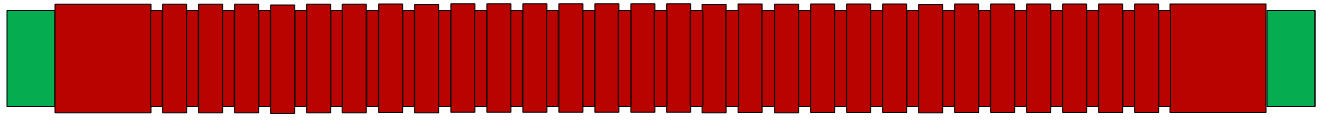

-Components

shown in green are of pipeline grade and red of high strength

material.